Automatic Under-leaver system

This paper dispenser is composed of a set of devices that offer a high performance to meet the new demands of production lines.

Overview

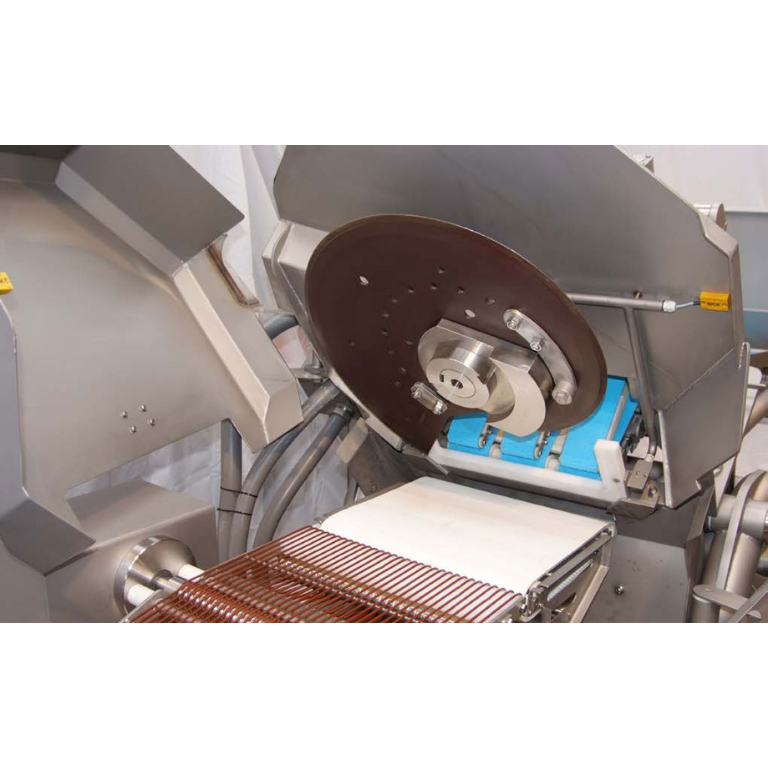

This solution receives the product from an input line, where a cord conveyor picks up the product and moves it to the dispensing unit.

In this unit, an automatic equipment dispenses fast and accurately the under leaver film under the product and places it on a second cord conveyor that takes it to the output.

Thanks to its features, the paper dispenser can adapt to the specific production requirements of each customer.

Key Features

Equipment maximum performance: 200 units/min (working with a paper length of 100 mm). The performance of the equipment will depend on the length of the paper.

Dispensed material: absorbent paper, wax paper, cellophane, etc.

Processed products: hamburgers, filleted meat, minced meat, etc.

Paper roll size tolerance: inner diameter 76 mm; maximum outer diameter 250 mm.

Specifications

Technical data

- Made in AISI 304 stainless steel.

- Electrical power supply: 230 V (50/60 Hz).

- Pneumatic power supply: 6 bar with clean and dry air.

- Touch screen control panel.

Configurations

- 1 lane for paper width up to 160 mm.

Accessories

- Stacking kit.

- Ethernet kit.

The solution

- It speeds the process of paper cutting and its placement under the product.

- Fast change of type of paper, thanks to the easy replacement of the under leaver paper roll.

- Easy removal of the dispenser for cleaning operations.